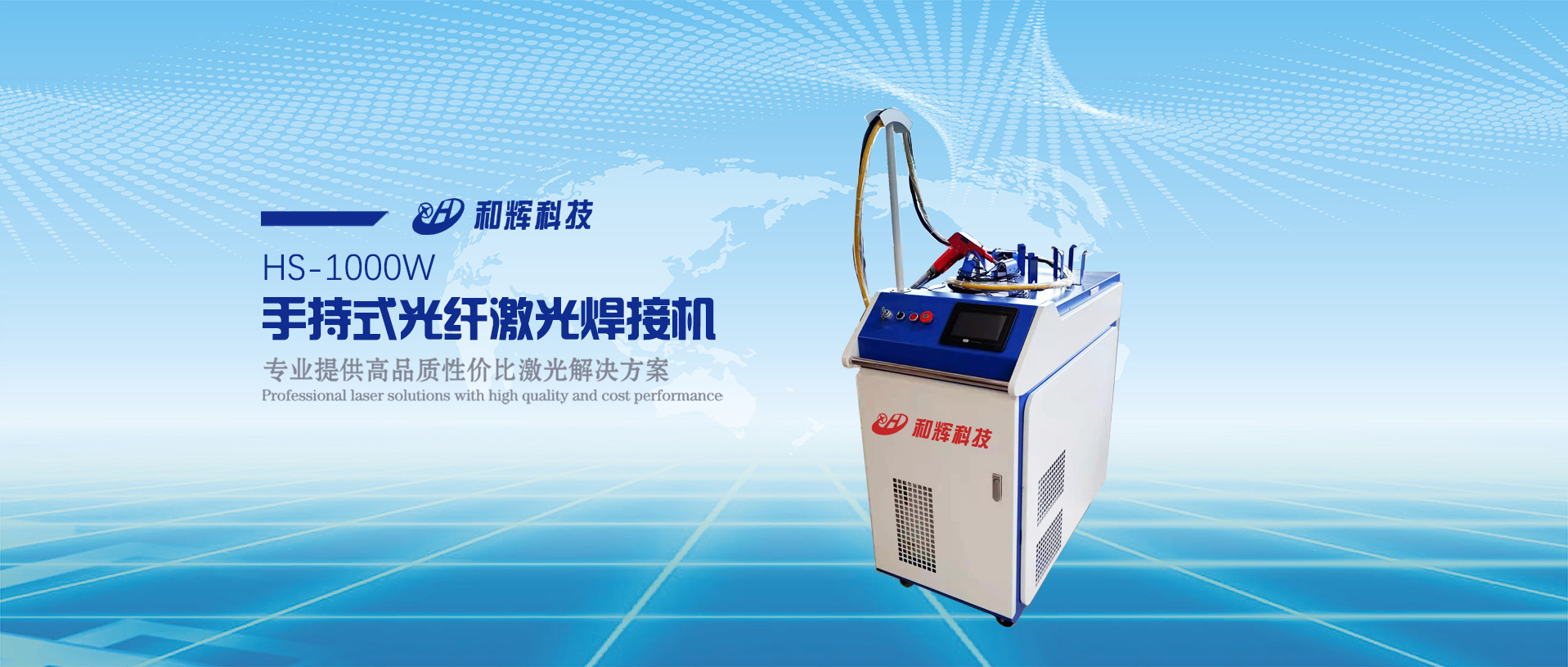

Continuous laser welding machine HJ-CH-500W-800W-1000W-1500W

Compared with other traditional welding skills, the main advantages of laser welding are:

1. Fast speed, large depth and small deformation.

2. It can weld refractory materials such as titanium, quartz, etc., and can weld the opposite sex data with outstanding effect.

3. It can be welded at room temperature or under special conditions, and the welding equipment is simple. For example, when the laser passes through an electromagnetic field, the beam does not shift; the laser can be soldered in vacuum, air, and a certain gas environment, and can be welded through glass or data transparent to the beam.

4. Micro soldering is possible. The laser beam can be gathered to obtain a small spot and can be accurately positioned, which can be used for the welding of small and small workpieces that are automatically produced in large quantities.

5. The laser beam is easy to realize beam splitting according to time and space, and can process multiple beams together and multi-station processing, which provides conditions for finer welding.

6. It can weld hard-to-reach parts and implement non-touch long-distance welding with great flexibility. Especially in recent years, the optical fiber transmission skills have been selected in the YAG laser processing skills, which has enabled the laser welding skills to be more widely implemented and used.