APPLICATION

Applied in kitchen and sanitary industry, household appliances industry, advertising industry, die industry, stainless steel doors and windows industry, handicraft industry, household goods industry, furniture industry, auto parts industry, etc. Mainly for stainless steel door and window welding, thickness of 0.1mm-2mm.

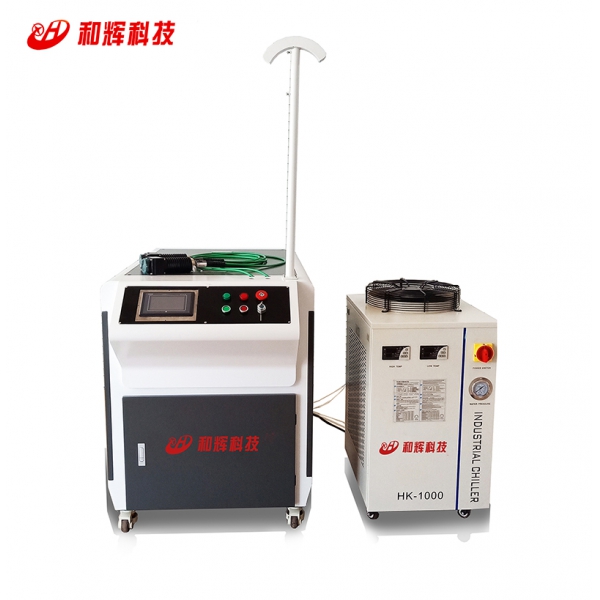

Working Principle of Laser Welding

Optical fiber continuous laser welding machine is a kind of laser welding equipment which couples high-energy laser beams into optical fibers and collimates them into parallel light through collimating mirror after long-distance transmission, and then focuses on the workpiece for welding. Flexible transmission non-contact welding is more flexible for parts that are difficult to access. It is currently used in sheet metal manufacturing, battery sealing, automotive parts and other industries. Laser beam of optical fiber continuous laser welding machine can realize time and energy splitting, and can process multi-beam simultaneously, which provides conditions for more precise welding. It is a new type of welding method, mainly for thin-walled materials and precision parts. It can realize spot welding, butt welding, overlapping welding, sealing welding, etc. It has high depth-width ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful weld seam. After welding, it does not need to be treated or only needs simple treatment, but also has good weld quality. no air hole, precise control, small focus point, high positioning accuracy, easy to achieve automation.

PRODUCT FEATURES

Laser welding machine can replace the traditional argon arc welding, with higher yield, better welding effect, beautiful weld, higher vacuum rate and other advantages. Laser welding can weld thin material products, and the weld seam is easy to polish, which solves the problems of argon arc welding easy to weld through and easy to produce welding nodules. Dual optical path continuous laser welding machine uses infrared positioning, process adjustment is more convenient and fast, training is simple, reduce the skill requirements of operators, operators can zero basic learning on the job.

<span style="mso-spacerun:'yes';font-family:" color:rgb(34,34,34);="" font-size:7.0000pt;mso-font-kerning:0.0000pt;"="" letter-spacing:0.0000pt;text-transform:none;font-style:normal;="">

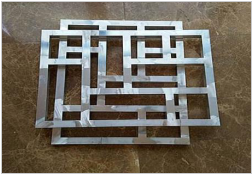

Obvious advantage contrast

In the traditional process, argon arc welding is used for stainless steel welding, but there are many defects in argon arc welding. The rate of good products is not satisfactory in aesthetics, but these problems can be improved by laser welding machine. Beautiful welding parts will not have distortion, and the rate of good products is higher, so stainless steel welding. Laser welding is faster and more efficient.

焊接方式 Welding mode | 热影响区 Heat affect zone | 热变形 Thermal deformation | 焊缝质量 Weld quality | 是否添加焊料 Add solder | 焊接环境 Environment |

氩弧焊 Argon arc welding |

较大 more |

较大 more |

一般 commonly |

是 yes | 需电极 Electrode Requirement |

激光焊接 Laser welding |

较小 less |

较小 less |

较好 preferably |

否 no | 无特殊需求 No special needs |