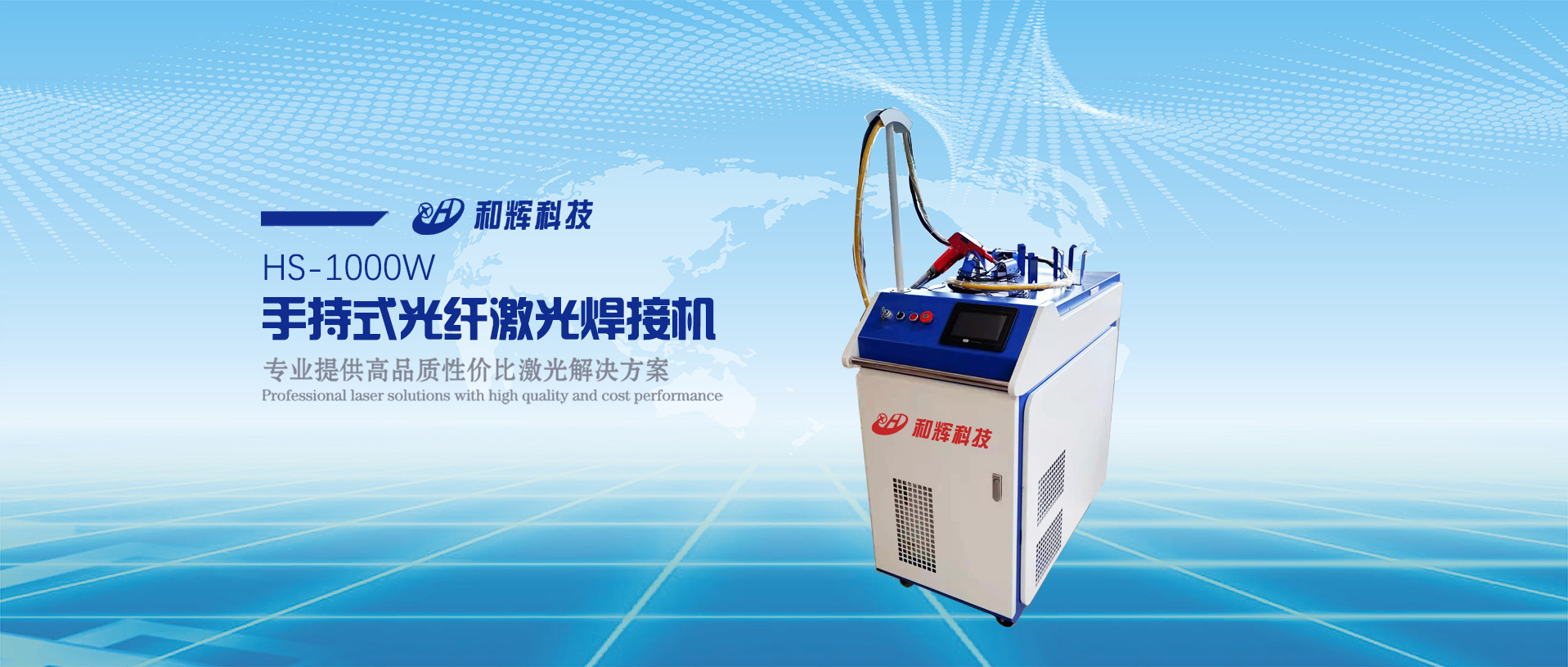

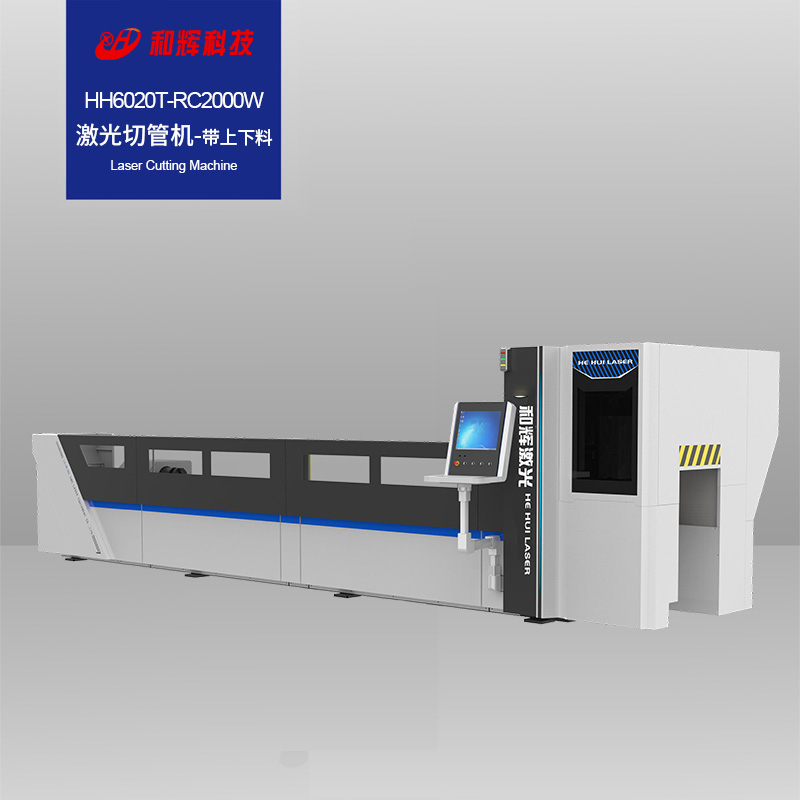

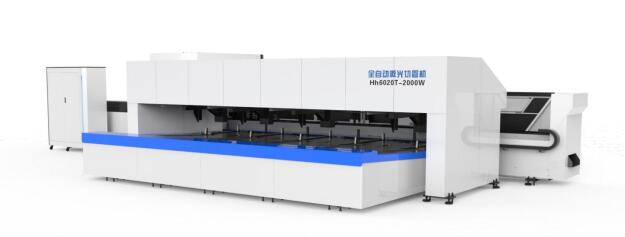

Hh6020T-RC2000W laser pipe cutting machine - with loading and unloading

First, the introduction of fiber laser cutting machine

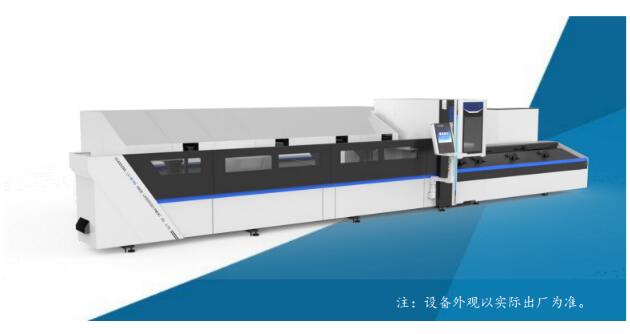

The bed of Hh6020T fiber laser cutting machine is annealed after the honeycomb carbon structure; the bed is welded by precision welding process, which has high strength and stability. The running speed of the machine can reach 80m/min. A square tube with a diameter of ≤200mm and a square tube with a side length of ≤140mm.The Hh6020T laser pipe cutter is equipped with a fully automatic loading and unloading device. For batch-processed workpieces, it is only necessary to place the workpieces in batches on the conveyor rack to complete the operations such as conveying, sorting, and robot feeding. After the processing is completed, the blanking part is equipped with an automatic blanking device, which can realize the automatic separation of the scrap and the finished material, the finished product falls into the finished material box, and the processing waste falls into the waste box, and for the workpiece with a long length, the configuration is Four groups of supports can be automatically adjusted according to the specifications of the workpiece, which protects the workpiece while improving the machining accuracy and quality, reducing labor intensity and improving work efficiency.

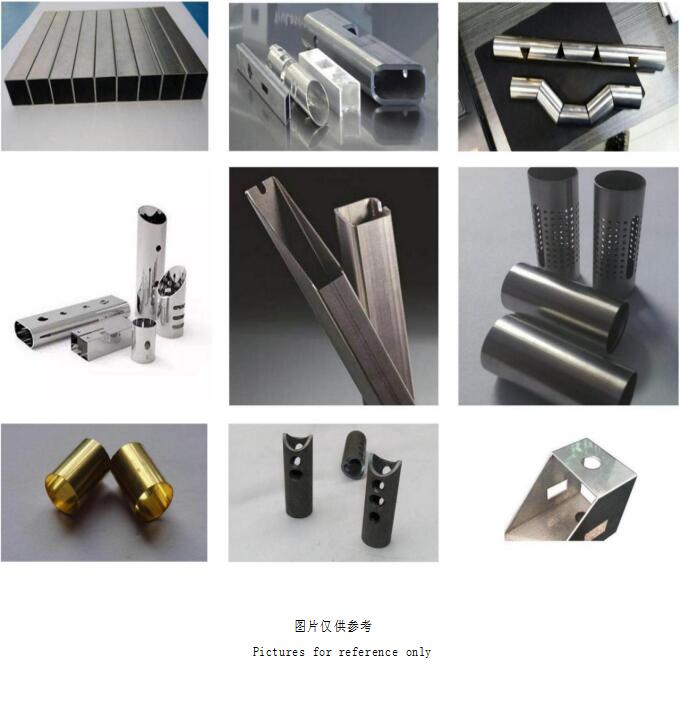

Second, the scope and ability of processing1. Application industry: rail transit, automobile, engineering machinery, agriculture and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, grain machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchen utensils, decorative advertising, laser external processing services And other machinery manufacturing and processing industries;2. Cutting materials: carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized sheet, silicon steel sheet, electrolytic board, titanium alloy, manganese alloy;3. Cutting range: 0.5~8mm carbon steel, 0.5~4mm stainless steel, aluminum alloy 0.5~4mm, brass 0.5~4mm;4, unique cutting function: flying fast cutting technology, aluminum alloy compressed air cutting technology.Cutting sample display

Part of metal material (round tube) cutting speed meter

材料Materials | 厚度thickness(MM) | 切割速度(m/min) Cutting speed | 气体 Gas |

管或铝管 Stainless steel tube or aluminum tube | 1mm | 18-20 | N2 |

2mm | 8-9 | N2 | |

3mm | 4.1-4.5 | N2 | |

4mm | 2.1-2.5 | N2 | |

5mm | 1.7-2 | N2 | |

6mm | 0.6-1 | ||

carbon steel | 1mm | 13-15 | N2 |

2mm | 4.2-4.8 | N2 | |

3mm | 4.1-4.5 | O2 | |

4mm | 3.1-3.5 | O2 | |

5mm | 1.7-2 | O2 | |

6mm | 1.6-1.9 | O2 | |

8mm | 1.5-1.7 | O2 | |

10mm | 1-1.3 | O2 |

Fourth, technical specifications

序号 Serial number | 技术指标 Technical indicators | 指标参数 index parameter |

1 | 光束质Beam quality(BPP,mm*mrad) | 1.27 |

3 | 管材切割直径范围 Pipe cutting diameter range | 20~200mm |

5 | 重复定位精度Repeatability | ±0.03mm/m |

7 | 电源额定参数 Power rating | Three-phase communication 380V 50Hz |

9 | 外形尺寸(长*宽*avout 13200*5100*2350 |

Main equipment configuration

主要配置清单Main Configuration List | ||

Model | 激光器 激光切割头 Hh | |

柏楚 TubePro | ||

Bed Machinery | LAPPING/SENFENG 法国电气、电路 日本法国大功率光纤激光切割机床High Power Fiber Laser Cutting Machine Tool | 冷水机 光纤切割专用除尘风机 光纤切割专用稳压器 说明书Instructions |

Five, various functional features1, fiber laser cutting hostThe main machine tool consists of the bed, Z-axis device, operation control part, gas path and other parts.Bed part:The machine tool adopts the German equipment layout mode, and the speed runs fast. The design and manufacture of the reinforced precision welded bed body and two aging treatments ensure the accuracy and stability of the long-term operation of the bed body, the rigidity is good, and the high acceleration can be accepted; the main bed It is made of steel structure precision welding, stress failure treatment, and large-scale gantry machining center for rail seats. 2, full-function CNC systemThe CNC system for laser pipe cutting machine was selected: TubePro pipe cutting software and TubesT pipe nesting software.Bai Chu TubePro Pipe Cutting Software is a professional cutting software for processing all kinds of pipes. Perfectly interfaced with the nesting software Tubest, Tubest handles part placement, co-edge, basic processes and special processes. Once the machining file has been exported, it can be cut directly using TubePro.(1) Automatic centering in processingTubePro can acquire Z-axis information in real time during machining to obtain the deviation between the center of the tube and the center of rotation of the chuck. Real-time compensation for subsequent patterns to be cut to achieve high-precision machining.(2) Workpiece mode and floating mode Workpiece mode and floating modeTubePro can select the machining mode before machining. The workpiece mode uses a fixed tool zero and is suitable for punching the cut pipe. The floating mode is based on the Y coordinate of the current cutting head, which is suitable for machining anywhere, anytime.(3) Seven-axis drawing material Seven-Axis Drawing MaterialTubePro supports two-cart seven-axis machines. After setting the seven-axis mode, the machining of the tailstock can be minimized by a moving chuck and a fixed chuck, thus saving customers more pipe material costs.(4) bracket BracketWhen machining a very long tube, a bracket is generally required to support the tube. TubePro supports the stand function. The bracket can be fully raised or lowered according to the position of the chuck during the whole process, and the bracket has an automatic alarm function to ensure the absolute safety between the chuck and the bracket. At the same time, the bracket can also be used to achieve the purpose of automatic cutting.5) Corner Craft Corner TechnologyTubePro has introduced the tube corner process specifically for the problem that the pipe corner is difficult to cut and cut. Set a reasonable set of corner pressure, peak power, duty cycle, etc. through the commissioning test to make the cutting at the corner of the pipe faster and more perfect.(6) Z-axis follow-up control Z-axis follow-up control systemWhen cutting the pipe, there is usually a corner that cannot be cut due to the Z-axis following instability or the follow-up response is not fast enough. When the TubePro is machining, the Z axis is not just a simple follow and lift, but also a control command. TubePro automatically calculates the height difference before and after the pipe rotation based on the cross-section information of the graph, and sends a rising or falling air-shift command to the Z-axis on the follow-up when cutting the corner.(7) Fast Leapfrog Fast leaping frogTubePro can ensure the reasonable height of the Z-axis based on the position of the pipe section of Western Sydney and the pipe hole to avoid unnecessary lifting. During the air movement, the XYB three axes move simultaneously with the Z axis, avoiding the up time and following time of the Z axis for more efficient machining.(8) Cutting of profiled steel Cutting of profiled steelTubePro not only supports the cutting of standard pipes such as round tubes and square tubes. It also supports the cutting of many profiled steels. Such as I-beam, channel steel, angle steel, elliptical tube, waist tube, polygonal tube, etc., and for these shaped pipes can also be automatically searched.Bai Chu TubesT pipe nesting software is a set of nesting software for Bai Chu pipe laser cutting CNC system, with Bai ChuCypTube/TubePro pipe cutting software enables the processing of drawings, co-edge nesting, weld compensation and other process settings and part drawing.(1) Nesting PackagingTubesT supports nesting of single or multiple parts, saving as much material as possible.(2) Special co-edge special CoplanarityTubesT can co-edge the parts after the weld compensation, and can also perform the same island or different parts for island co-edge processing to achieve the ultimate co-edge, reduce the number of cutting times, save time and money.(3) Quick import Quick importTubesT can automatically identify the IGS file stretching direction, and can import IGS files of different cross sections in batches at one time; support the import of assembly files, greatly improving the efficiency of file import.(4) Drawing processingFor the common problems in pipe cutting, such as the requirements of perforation accuracy, tube splicing and anti-interference, TubesT has a variety of graphic processes for users to handle, simple and flexible processing methods allow users to greatly shorten the drawing processing time.(5) Automatic sorting Automatic SortingAll pipes (including shaped pipes) can realize automatic sorting of the shortest moving path; for the most common rectangular pipes and round pipes, two automatic sorting strategies are provided by face sorting and sorting by circle to achieve a more reasonable processing path.(6) Processing of special steel sections Processing of special section steelIt supports the extraction and editing of the blade of angle steel such as angle steel, channel steel and I-beam, and can realize the common edge nesting of special steel, which greatly expands the processing capacity of the pipe cutting equipment.(7) Drawing parts Drawing PartsTubesT comes with 3D drawing function, users can also get started quickly with zero 3D drawing experience. Users can easily realize stretching, punching, cutting, V-groove and so on.(8) Layout report Layout ReportSimple layout report for easy operator kanban processing. Sixth, equipment operation cost analysis

项目project | 方案一:空压机组切割Scheme 1: Air compressor cutting | 方案二:氧气切割Scheme 2: Oxygen cutting | 方案三:氮气切割Plan 3: Nitrogen cutting | |

电力消耗 (峰值耗电量) Power consumption (Peak power consumption) |

激光器laser |

8KW |

8KW |

8KW |

Power consumption (Peak power consumption) | 冷水机功率Chiller power |

3.6KW |

3.6KW |

3.6KW |

Power consumption (Peak power consumption) |

空压机功率Air compressor power |

11KW |

3.6KW |

3.6KW |

Power consumption (Peak power consumption) |

机床主机Machine Tool Host |

20KW |

20KW |

20KW |

Power consumption (Peak power consumption) | 排尘设备Dust removal equipment | 3KW | 3KW | 3KW |

易耗件Consumable parts | 0.5 RMB/H | 0.5 RMB/H | 0.5RMB/H | |

气体消耗Gas consumption | 0 | 15 RMB/H | 60 RMB/H | |

总功率Total power | 45.6KVA | 34.6KVA | 34.6KVA | |

总耗电量(取 60%切割效率)Power Consumption (60% cutting efficiency) |

27.4KW/H |

21KW/H |

21KW/H | |

总运行成本 (按 1RMB/kwh) Total operating cost (1 RMB/kwh) |

27.9 RMB |

36.5 RMB |

81.5 RMB | |

Seven, "peak cloud" system

The client uses the browser to display the dynamic surface of the real-time data, and allows the client to perform remote engineering development and engineering maintenance on the client side with sufficient permissions. Clients running on mobile phones, PDAs, etc., display the monitoring interface in real time and change data values, confirm alarms, etc. in text mode.

1. With "expert system" to achieve product positioning, track query, remote fault diagnosis, equipment fault history query function. Transfer data to clients, other monitoring points, and servers through the Internet/5G network.2. "Fengyun" system intelligently collects equipment status and fault information for analysis, and calculates production cost and maintenance cost according to a certain algorithm, and obtains a high-quality cost-effective solution for product design, which saves manufacturing cost for the enterprise.3. “Fengyun” system is powerful, and can be equipped with remote diagnosis and maintenance, redundancy, real-time historical data recording, scheduling, recipe, video and audio, etc. It has rich drive types and script functions, and has many standardized interfaces. It can be connected efficiently to the MES system of the customer's factory.4. With the advent of the 5G era, the “Fengyun” system will use 5G technology to combine laser equipment and artificial intelligence, and widely used in cloud computing, big data and edge computing, making advanced and complex laser equipment More and more presentations, intelligent, easy to use, and popularized, provide customers with faster and more convenient global remote diagnosis services.